Custom Nanoparticles for Electronic Devices

Avantama are world leaders in the development and production of custom nanoparticles. These nanoparticles are specifically useful for printed electronic devices, which are traditionally expensive to manufacture. This blog post will outline the custom nanoparticle solutions available from Avantama, and their applications.

Avantama Nanoparticles

At Avantama we have a wealth of knowledge regarding the engineering of nanoparticles, and we are able to produce custom nanoparticles to specific requirements.

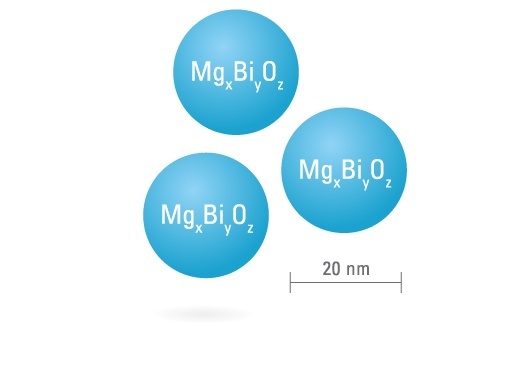

The range of custom nanoparticle products available is broad, including simple or complex oxide nanoparticles, doped nanoparticle, or advanced salt nanoparticles. These particles can be produced according to exact requirements in any composition.

Custom nanoparticles from Avantama are available with rapid screening due to the flexibility in nanoparticle composition and the size of these nanoparticles can be fine-tuned between 5 nm and 50 nm.

The particle size distribution of these nanoparticles is narrow and can be optimized for specific requirements. Additionally, these nanoparticles are produced with a high phase purity, and a specific elemental purity can also be requested.

Nanoparticles for Electronic Devices

Within electronic devices such as OLED lighting or printed solar cells, the display is often the most expensive component. This is due to the materials used the processes employed by the electronics industry to construct these displays. The displays are often constructed via vacuum deposition of inorganic layers.

An OLED (Organic Light Emitting Diode) is a device that emits a flat light, which is produced by layering a series of thin films between two conducting materials. When electricity is applied, OLEDs generate light, making them useful for displays and lighting. Generally, the light emitted from OLEDs is generated in different directions and propagates via various modes. This can result in a considerable loss of light, and the total internal reflection can be as high as 80%, causing a very dim light.

Using Avantama custom nanoparticles as an alternative method of construction for these displays has considerable benefits.

Today, most OLED devices are manufactured via vacuum processes. Firstly, the custom nanoparticles would be deposited via a printing technique, which is significantly cheaper than other methods. The temperatures at which this process is undertaken is also a lot lower. Custom nanoparticles from Avantama can be used as charge transport layer, high refractive index planarization and scattering.

In addition to improving the manufacturing process of printed electronics, custom nanoparticles can also substantially improve the quality of the electronic device.

Solar panels, can often suffer from reflection issues that impact their performance. Anti-reflection multi-layer coatings, created using custom nanoparticles provide a cost-effective method to resolve this issue. These nanoparticles can alter the refractive index of the glass surface to reduce the reflection from around 8% to 0.6%.

Avantama technology enables the development of high-quality coatings using custom nanoparticles for electronic devices. If you would like any more information about our range of custom nanoparticles, please contact us.